HAWK

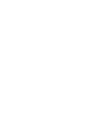

A revolutionary deck motion monitor system, providing added safety and efficiency when transferring cargo and crew by crane.

Why HAWK?

Offering precise data, better communication and clearer vision, HAWK has transformed the process of crane transfer.

As an alternative to the traditional measure of Significant Wave Height, HAWK uses Effective Significant Wave Height to determine safe operating limits. This accurate measurement of deck velocity presents an all-round, real-time picture of conditions to help you work safer, smarter and longer.

- Accurate wave input for the crane’s safe load indicator.

- Improved personnel safety.

- Easy to make safe decisions.

- Less waiting on the weather.

- Better timing and control of the lift.

- Easy installation and low maintenance.

- Proven in the Norwegian sector for almost 10 years.

“The good thing with the HAWK system is that it is very easy to understand and use. It can be a very useful tool when placing a heavy lift on the vessel deck in harsh conditions.”

Ekofisk field Crane Operator

ConocoPhillips

The benefits

Lower vessel costs

Support vessels represent an ever-increasing cost for offshore operations. Often, the safe and efficient loading of cargo and crew is a major contributor to these costs.

Following the standard defined in EN13852, current methods of establishing crane operational limits can be too conservative. This guidance also doesn’t take into account the other factors that impact on actual deck velocity, such as variations in vessel dimensions, orientation of the vessel and weather conditions.

By using real-time measurements of actual vessel movements, we’re able to reduce waiting times by 50%, resulting in game-changing financial savings.

Accurate wave data

The HAWK system displays the Effective Significant Wave Height, real time waves, and a live video feed from the supply deck. This accurate wave data provides crane operators with an excellent alternative to the simplified Significant Wave Height method used today.

As a result, HAWK markedly increases both safety and availability to offshore lifting operations.

Proven track record

HAWK has proven its durable performance since 2007. It’s been well received by operators on the North Sea’s Ekofisk field, and is now installed on 21 cranes and eight platform support vessels.

The availability of lifting operations has increased significantly compared to the use of the traditional method. As the sea state changes, HAWK is easily used to decide whether to start, delay or stop the operation.

In 2007, DNV carried out field trials to assess the merits of HAWK alongside older wave radar in the Ekofisk field. The results showed that using HAWK created a far wider operating envelope in comparison to wave radar.

Request a quote

Get in touch to find out more and discuss how HAWK can improve your operations.

_180_144.png)